Completeness Check

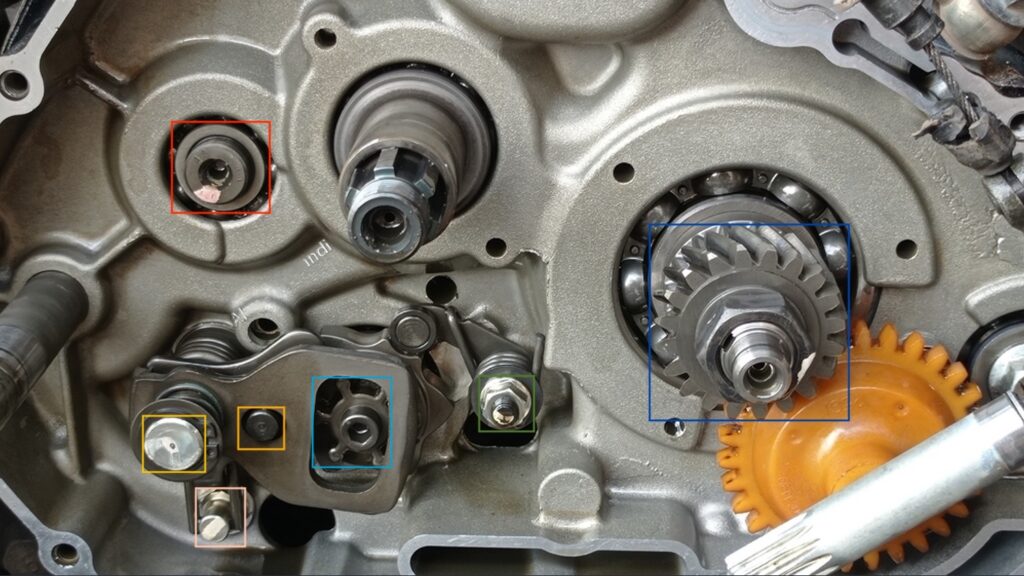

Assembly Verification Application

Completeness Check

Assembly Verification Application

Identify missing pills in blister packs, check meal trays, Check for foreign particles in food/pharma or any other Absence/ Presence Application.

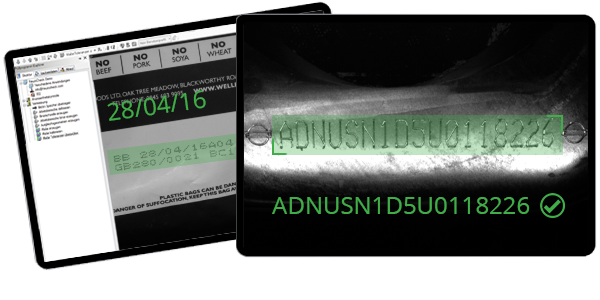

Text OCR

Applications

Read Labels for text, barcodes, expiry date with accuracy. OCR Applications are deployed in Expiry date verification, Barcode verification, reading Batch numbers, Digitising Seven Segment dipalys and Many more.

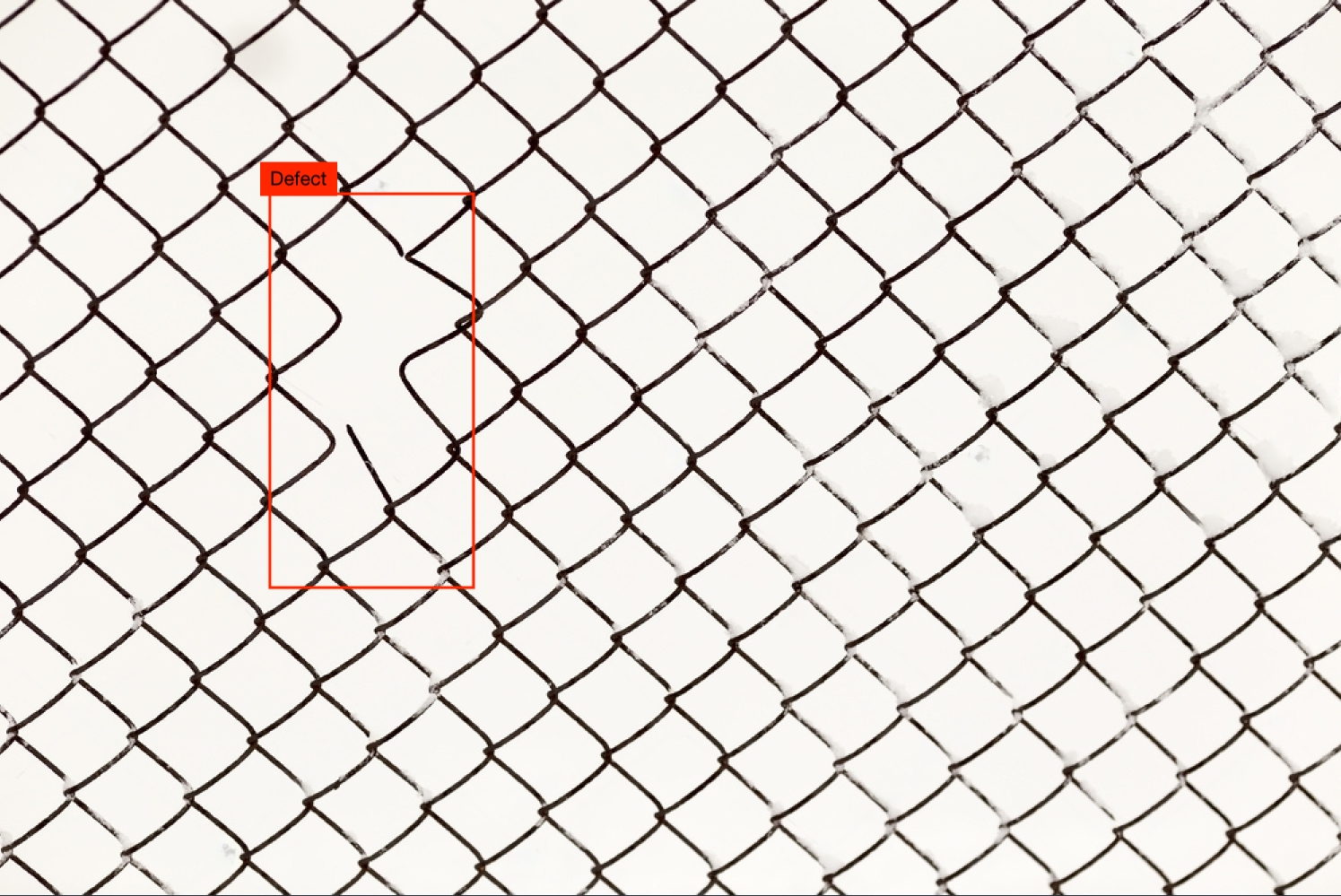

Surface Inspection

& Defect Defection

Defect Detection with quick deployment? Used widely in packaging inspection, PCB inspection, Textile inspection , Paper defect detection etc.

Classification

and counting

Count your parts and identify them too! Widely deployed in use cases like Nut/ Bolt identification and counting, Biscuit counting, Diamond Counting , Candy Counting and Many more.

100% quality inspection

client satisfaction

0-4 PPM

increased efficiency

USP

100% tailor-made solutions promise exceptional performance and accuracy for the use case

All solutions are based one-time cost and these can be deployed on-premise as well

We design the entire vision system including hardware design, camera selection , lens selection and software, promising robustness and repeatability.

Any type of integration is possible.

We do Computer Vision. Do it Right.

Our focus is to deliver computer vision systems that you can rely upon. We use a sophisticated combination of deep learning and Image processing to render highly accurate results. We understand that new problem statements require custom solutions and hence we tailor design and customize the entire vision system to meet toughest of the requirements.

Since all our systems are deep learning based, issues like lighting change, orientation, color change, background change etc do not interfere with the systems performance.

IF A HUMAN CAN SEE IT, OUR CAMERA CAN SEE IT EXACTLY THE SAME WAY.

Industries We Serve

How We Work

Free 30min consultation video call

Schedule a free call to discuss your use case and pain points for us to suggest you the right solution.

Collect Images from the Production line and use them to train Defect Detection Model.

After collecting images, we showcase the capability and the accuracy in your environment. Your satisfaction is utmost important.

Industrial Deployment

After Successful proof-of-concept, we will design the vision system and ready to deploy in-line.

Past/Upcoming Exhibitions

How it all comes together:

We take 200-500 labelled images of your product and then run it through our in-house image augmentation scripts. These images are then increased by 10x to flood the model with USEFUL data.

We use the new augmented data to train our proven AI models to learn the slightest and the tinniest changes/ features in your product.

We test the accuracy of the AI model and fine tune it further. After we achieve the desired accuracy, we develop the custom application layer and as well as work on CUSTOM INTEGRATIONS to enable you to perform actions/ get analytics that you really desire.

All our systems are hardware agnostic.

Recent Blog Post

Enhancing Engine Number and Vehicle Identification with Hand-Held Cameras with AI

In the bustling landscape of the two-wheeler industry, precision and efficiency are paramount. Ensuring

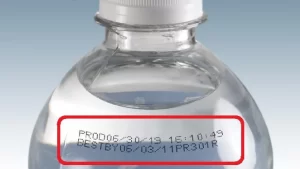

Advancing Defect Detection on Curved Surfaces: AI Powered Batch Code Verification ( OCV) on Shampoo/ Beverage Bottles

In modern manufacturing, batch codes play a vital role in product traceability and quality control.

Enhancing Manufacturing Quality: AI based Assembly Verification Systems for Engine Assembly

In the realm of modern manufacturing, ensuring the highest level of quality is paramount. One